03 Nov Energy: Flywheel Startup Temporal Power

What are flywheels?

A 500 kW flywheel being lowered into the vault at flywheel company Temporal Power’s manufacturing facility to undergo testing (Image: Temporal Power).

Lux Research, an independent firm that assesses emerging technologies, predicts that the global energy storage market will grow from a $200 million industry in 2012 to an $11 billion giant by 2017. Chemical batteries have recently made some strides forward and many more companies have jumped on board. However, the most promising way of storing energy for the future might come from a more unlikely source, and one that far predates any battery: the flywheel.

A flywheel is nothing more than a wheel on an axle which stores and regulates energy by spinning continuously. The device is one of humanity’s oldest and most familiar technologies first used in the potter’s wheel 6000 years ago as a stone tablet with enough mass to rotate smoothly between kicks of a foot pedal. Leonardo da Vinci invented one with a variable moment of inertia. It was an essential component in the great machines that brought on the industrial revolution. Today, flywheels are under the hood of every car – regulating the strokes of pistons.

Interested in more of my posts and other writings outside of Impact Hound? Follow me on Twitter: @shenge86

The physics in energy storage of flywheels is simple. It is directly proportional to the mass of the rotor multiplied by the square of its rotational speed. This formula has interesting implications since if the rotor speed doubles, the stored energy will increase by four times without any increase in the mass of the rotor. However, there is a limit to the rotational speed since it will warp or shatter if spun faster than the design and material can handle.

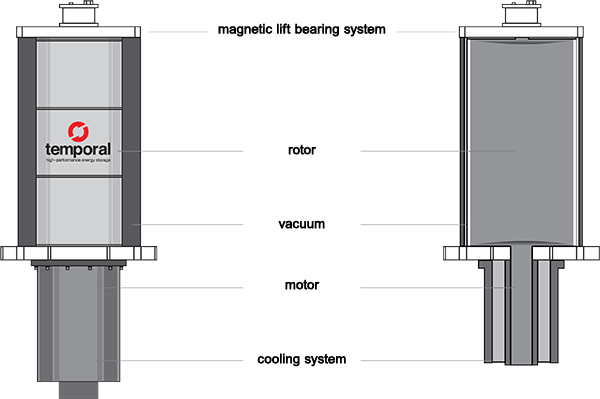

Modern flywheels are quite sophisticated. They store energy kinetically in a rotating mass called a rotor made of steel or high tensile strength carbon fiber. The rotor contains a variable speed motor and generator. It’s housed in a vacuum chamber to eliminate air friction. The rotor and its motor and generator setup are also magnetically levitated to further reduce friction losses to almost zero.

Flywheels can theoretically last for decades, which is a perfect match for utility markets that prize longevity, durability and performance. Unlike chemical batteries, mechanical flywheels don’t lose storage capacity due to the number of charge and discharge cycles they incur.

Flywheels do have three main disadvantages though:

- Flywheels that store a lot of energy are not portable. They weigh thousands of pounds. However, weight is not a major issue for some grid-scale applications.

- Since there’s very high-speed rotating mass, special precautions must be taken to insure safety. Flywheels are typically placed underground for this reason. As with the weight issue, this is not a negative factor for many grid applications.

- Cost has been a big issue, especially for flywheels that use expensive carbon fiber as the rotating mass.

Temporal Power Does Things Differently

Schematic design of the flywheel Temporal Power manufactures (Image: Temporal Power).

Currently, there are few companies pursuing flywheel which leaves the market wide open for new technologies to be developed. One of the rising stars is Temporal Power. Based in Ontario, Temporal Power uses solid-steel flywheels as a method of storing electrical energy. Enbridge, the largest solar energy generator and second-largest wind generator in Canada, and venture capital firm Northwater Intellectual Property Fund has invested $13.5 million to date in Temporal Power.

Temporal Power has achieved radical cost reduction by deciding to use aerospace quality steel to manufacture its 9000 pound (4000 kilogram) rotors instead of using carbon fiber. While steel cannot spin as fast (12,000 rpm here), Temporal believes the cost performance of the steel is significantly better. Steel is also much easier and less expensive to apply in the manufacturing process. For a commercially viable product, typically, the most cost-effective product wins over the most advanced technologically. An example is Beacon Power which went bankrupt in 2011 with its focus on carbon fiber flywheels.

Temporal Power also has achieved adaptability. Let’s give an example. A flywheel for a solar PV array might need a minute or two of duration which is not much energy but high power. In contrast, a flywheel providing short-term spinning reserve for a wind farm will need to last longer, requiring a lower power-to-energy-ratio. The more flexible the power-to-energy-ratio, the more applications can be done by the device. Temporal Power’s flywheels can be scaled to provide anywhere from about 2 megawatts to 100 megawatts. They can operate for up to six minutes at its full rate of power.

Currently, the company has two pilot projects in vastly different scales of power-to-energy-ratios. One is with Hydro One and another is with Ontario’s Electricity System Operator. For the former, Temporal Power will provide up to ten 500-kilowatt flywheels (5 megawatts) for frequency regulation on a feeder that is connected to two 10-megawatt wind farms in southwest Ontario. For the latter, Temporal Power will deliver 2 megawatts of regulation service to the Independent Electricity System Operator (IESO) in Ontario.

Story behind Temporal Power

Temporal Power was started by an engineer and tinkerer named Jeff Veltri. A non-work-related injury at an early age ended Jeff Veltri’s five-year job as a pipe fitter and sent him back to school into Ryerson University’s mechanical engineering program. He was employed for a while and then started his own firm, working over the next ten years on industrial, biomedical and military projects.

As Veltri mused about flywheel use for his own business, he realized it could be commercialized for grid use. So he designed a small prototype and took it to the OPA (Ontario Power Authority) to show it off. The device had an analog power meter with a disc that spun one way when the machine was charging and the other way when it was discharging, which gave a good visual demonstration.

To move forward, the next step was obtaining a $300,000 OPA Technology Development Fund grant, but applying would involve business model expertise. “I hired Cam Carver, and he was very enthusiastic,” Veltri explains. “He suggested partnering and creating a new business, and we formed Temporal Power in 2010 [Veltri is President and CTO, and Carver is CEO]. The management of grids was changing and Cam realized the concept would be of great value to the IESO (Independent Electricity System Operator of Ontario) in terms of frequency regulation.”

A Bright Future Ahead

The company secured the OPA grant, which allowed the tech to be scaled up to bench size, a 1 kW model. Carver and Veltri secured further investment of half a million dollars from MaRS Discovery District, and several million dollars from a Toronto-based venture fund, allowing the company to move to a facility in Mississauga. As of October 2014, they are now at 30,000-sq.-ft. with 24 full-time employees, including eight engineers. They now offer commercially a 50kW, 250kW, and 500kW module that can be arrayed to multi megawatt scale. Assuming the pilot projects works well, a low-cost and adaptable flywheel system is coming right in time to handle the world’s exponential rise for energy storage.

Interested in more of my posts and other writings outside of Impact Hound? Follow me on Twitter: @shenge86

References

[2] http://www.damninteresting.com/the-mechanical-battery/

[3] http://www.energystrategiesgroup.com/temporal-power-ltd-a-company-to-watch/

[4] http://www.enbridge.com/Viewer?id=BC51836DC0A34B4E93A338599298E570

[5] http://www.greentechmedia.com/articles/read/hydro-one-picks-a-new-flywheel-for-wind-balancing